La Suisse est souvent réduite à ses clichés : le chocolat, les banques et les montres de luxe. Pourtant, derrière l'image d'Épinal se cache une réalité industrielle vibrante, moteur discret mais puissant de l'économie nationale. En 2026, alors que le monde traverse des turbulences économiques, la microtechnique suisse fait figure de bastion de stabilité et d'excellence. Pour l'ingénieur passionné comme pour le technicien spécialisé, ce secteur n'est pas seulement un gisement d'emplois ; c'est une promesse de participer à l'élite technologique mondiale.

Mais attention, le paysage change. L'époque où il suffisait de se présenter pour être embauché laisse place à une ère plus sélective, dictée par le renchérissement et la rationalisation des coûts. Comprendre les dynamiques salariales, l'impact de la nouvelle CCT et les exigences des partenaires sociaux est désormais vital pour quiconque souhaite naviguer dans cet écosystème. Ce guide n'est pas une simple brochure ; c'est votre feuille de route pour décrypter les opportunités réelles dans un marché où la Suisse reste, malgré les défis, le leader mondial incontesté de la précision.

Comprendre la microtechnique

Définition et importance de la microtechnique

La microtechnique ne se limite pas à faire "petit". C'est l'art d'intégrer des fonctionnalités complexes dans des volumes minuscules, à l'échelle du micron. C'est la convergence de la mécanique, de l'électronique, de l'optique et de l'informatique. Dans un monde où la miniaturisation est reine, cette discipline est la clé de voûte de l'innovation moderne. Elle permet de concevoir des produits services à haute valeur ajoutée qui redéfinissent notre quotidien.

Loin d'être une industrie du passé, elle est le socle sur lequel reposent les avancées les plus critiques. Sans microtechnique, pas de smartphone, pas de chirurgie non invasive, pas de capteurs pour les véhicules autonomes. Elle est l'invisible indispensable.

Applications et secteurs d'utilisation

Les applications sont aussi vastes que la précision est fine.

- Santé et MedTech : C'est sans doute le domaine le plus impactant. Des pacemakers de la taille d'une gélule aux pompes à insuline intelligentes, la microtechnique sauve des vies. À Lausanne, hub de l'innovation médicale, les entreprises développent des technologies qui permettent à des paraplégiques de remarcher grâce à des implants neuronaux.

- Horlogerie : Secteur historique par excellence. L'industrie horlogère suisse reste le standard absolu, mais elle évolue. La montre connectée hybride, mêlant mouvement mécanique et capteurs vitaux, est l'exemple parfait de cette mutation.

- Automobile et Aérospatial : La sécurité des véhicules modernes dépend de micro-capteurs (ABS, airbags, lidars). Ici, la tolérance à l'erreur est nulle, et la qualité suisse fait loi.

- Robotique et Automation : Avec l'essor de l'intelligence artificielle robotique, les besoins en actionneurs et capteurs ultra-précis explosent.

La microtechnique en Suisse : un secteur en plein essor

Présentation des statistiques et des données factuelles

Affirmer que le secteur est en plein essor peut sembler paradoxal dans le contexte économique ralenti de 2026, mais les fondamentaux confirment une croissance structurelle. Si les volumes de production de masse peuvent fluctuer, la valeur ajoutée, elle, grimpe.

Les industries horlogère microtechnique emploient plus de 60'000 personnes en Suisse. En 2025, malgré un ralentissement des exportations vers l'Asie, le chiffre d'affaires global du secteur s'est maintenu grâce à la diversification vers le médical et l'industriel de pointe.

Les données salariales pour 2026 sont claires : le salaire médian de référence dans la branche horlogère a atteint CHF 5'958.-. Ce chiffre témoigne de la résilience du secteur face aux pressions économiques.

Témoignages d'experts et réalité du terrain

"La Suisse n'est pas un musée, c'est un laboratoire", affirme un directeur R&D basé à Zurich. Selon les experts, la force de la Suisse réside dans sa capacité à faire dialoguer tradition et futur. Les partenaires sociaux parvenus à des accords solides garantissent une paix du travail unique au monde, favorisant les investissements à long terme. Contrairement à d'autres pays où les grèves peuvent paralyser la production, la Suisse privilégie le dialogue, assurant une continuité rassurante pour les clients internationaux.

Opportunités de carrière en microtechnique

Liste des différents postes et rôles dans le domaine

Le secteur recrute, mais les profils changent. Voici les rôles clés en 2026 :

- Ingénieur en microtechnique : Le chef d'orchestre. Il conçoit les systèmes et supervise leur intégration. Dans recherche développement, c'est le profil le plus chassé.

- Micromécanicien / Régleur CNC : Les mains d'or. Capable de programmer et régler des machines à 5 axes pour usiner des pièces invisibles à l'œil nu. La pénurie sur ce poste reste critique.

- Qualiticien : Garant de la norme. Dans le médical ou l'aérospatial, la traçabilité est totale. Le qualiticien ne se contente plus de contrôler ; il prévient les dérives.

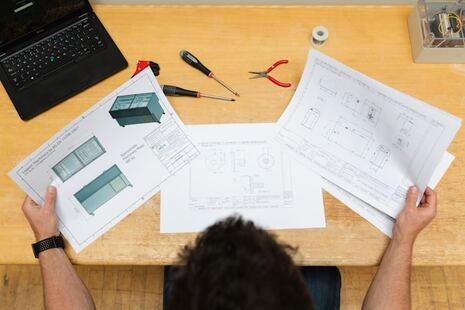

- Dessinateur-constructeur : Le visionnaire technique. Il traduit les concepts des ingénieurs en plans réalisables, maîtrisant la CAO sur le bout des doigts.

Compétences requises pour chaque poste

Au-delà du diplôme, des compétences spécifiques ("Hard Skills" et "Soft Skills") sont exigées :

- Rigueur absolue : L'erreur d'un micron peut coûter des millions.

- Polyvalence linguistique : L'anglais technique est la base, l'allemand un atout majeur pour travailler avec les fournisseurs outre-Sarine.

- Adaptabilité aux nouvelles technologies : L'impression 3D métallique, le décolletage laser et l'intégration de l'IA dans les processus de production demandent une formation continue constante.

- Esprit d'équipe : La complexité des produits rend le travail solitaire impossible. La collaboration entre le bureau d'études et l'atelier est la clé du succès.

Préparation pour une carrière en microtechnique

Éducation et formation nécessaire

La Suisse brille par son système dual formation travail.

- Apprentissage (CFC) : La voie royale. Le CFC de micromécanicien ou de dessinateur est reconnu mondialement. C'est l'assurance d'un emploi à vie et d'un salaire décent dès la sortie de l'école (environ CHF 4'500 - 5'000 pour un débutant qualifié).

- Hautes Écoles (HES / EPF) : Pour les ingénieurs. L'EPFL (Lausanne) et l'ETH (Zurich) sont régulièrement classées parmi les meilleures universités techniques du monde. Elles forment l'élite qui pilotera l'innovation de demain.

- Formation continue : Avec l'évolution rapide des metiers, se former tout au long de la vie est impératif. Les brevets fédéraux permettent aux techniciens de grimper les échelons vers des postes de management ou d'expert.

Conseils pour entrer dans le domaine

- Viser les PME, pas seulement les géants : Si Rolex ou Swatch font rêver, le tissu industriel suisse est composé de milliers de PME hyper-spécialisées (décolletage, traitement de surface) qui offrent souvent plus d'autonomie.

- Maîtriser la convention : Connaître la convention travail cct montre votre sérieux. Savoir que les salaires minimaux ont été revalorisés ou que la compensation renchérissement est négociée chaque année vous donne l'avantage en entretien.

- Réseauter localement : Participez aux salons comme EPHJ à Genève ou aux journées techniques à Neuchâtel. C'est là que le marché caché se dévoile.

Cas de succès dans la microtechnique en Suisse

Présentation de 2-3 études de cas réussies

- Cas 1 : La pivot de la vallée de Joux. Une PME familiale, historiquement sous-traitant horloger, a frôlé la faillite. En réorientant ses machines pour produire des aiguilles chirurgicales, elle a non seulement sauvé ses emplois mais a doublé son chiffre d'affaires en trois ans. Leçon : la technologie est transférable, l'agilité est la clé.

- Cas 2 : La Start-up Lausannoise. Issue de l'EPFL, cette jeune pousse a développé un micro-moteur pour drones de surveillance. En s'associant très tôt avec un partenaire industriel à Zurich pour l'industrialisation, ils ont réussi à passer du prototype à la série en 18 mois. Leçon : l'innovation seule ne suffit pas, il faut savoir s'industrialiser.

- Cas 3 : Parcours d'un apprenti. Thomas, apprenti micromécanicien à Bienne, a remporté les SwissSkills. Aujourd'hui, à 26 ans, il dirige une équipe de 10 personnes et gère des projets pour l'agence spatiale européenne. Leçon : la voie professionnelle en Suisse n'a pas de plafond de verre.

Perspectives futures pour la microtechnique en Suisse

Prévisions sur les tendances futures

L'horizon 2026-2030 est marqué par la digitalisation. L'intelligence artificielle robotique va transformer l'atelier. Les machines s'auto-corrigeront en temps réel.

Le Conseil fédéral pousse également pour une industrie plus verte. L'éco-conception et le recyclage des métaux précieux deviennent des critères de compétitivité majeurs.

Enfin, la sécurité travail sera renforcée par des exosquelettes et des interfaces homme-machine plus ergonomiques, réduisant la pénibilité pour les travailleuses travailleurs.

Opportunités potentielles à venir

La fusion entre la biologie et la microtechnique (BioMEMS) est le prochain Eldorado. La Suisse, avec son bassin pharmaceutique et technique, est le lieu idéal pour cette révolution. Les investissements massifs dans ce secteur promettent des milliers de nouveaux emplois hautement qualifiés.

Conclusion

La microtechnique suisse est à un tournant. Entre tradition séculaire et futurisme radical, elle offre des carrières passionnantes à ceux qui acceptent l'exigence de l'excellence. Que vous soyez à Zurich, Lausanne ou au cœur du Jura, les opportunités existent. Mais elles se méritent. Se former, comprendre les enjeux économiques comme le rencherissement, et s'adapter aux nouvelles donnes de la politique industrielle sont les clés de votre réussite. N'attendez pas que le futur arrive, usinez-le.

Les défis de la microtechnique en Suisse

Le tableau n'est pas sans ombres. Le franc fort reste un défi constant pour les exportations, obligeant les entreprises à une productivité hors norme pour compenser les coûts.

La pénurie de main-d'œuvre qualifiée, bien que s'atténuant légèrement en 2026, reste structurelle. Attirer les jeunes vers les métiers techniques est une priorité nationale.

Enfin, la reforme lpp (prévoyance professionnelle) et l'augmentation des coûts de la santé pèsent sur les charges salariales, complexifiant les négociations entre partenaires sociaux. La solution passe par l'innovation : produire mieux, avec moins de ressources, pour justifier le label "Swiss Made".

Le rôle de la microtechnique dans l'économie suisse

Ce secteur est le système nerveux de l'économie helvétique. Il ne représente pas seulement des parts de marché, mais une culture de la fiabilité qui irradie sur tous les autres secteurs, de la banque (sécurité des data centers) aux transports. Suisse pays de la précision, c'est une marque employeur qui attire les talents du monde entier. En maintenant ce leadership, la Suisse assure sa souveraineté technologique face aux géants américains et asiatiques.

Ressources Externes

- Convention Patronale (CPIH) : Données officielles salaires et CCT

- SwissSkills : Promotion des métiers techniques

- Unia : Informations sur les conventions collectives

Sources utilisées

- [1.3] CPIH - Salaires médians de référence 2026

- [3.4] Communiqué CPIH/UNIA Octobre 2025 : Accord sur la compensation du renchérissement (+12 CHF ou 0.2%).

- [3.1] Conjoncture 2026 : Baisse des effectifs et incertitudes (CPIH).

- [2.2] Réforme AVS/LPP : Impact 2026 et 13ème rente.